- Want to know how a Laminar air flow works?

- Willing to understand what a laminar airflow is?

- What are the benefits of using a laminar airflow in a biotech lab?

Here, in this blog, you will get the answers to all such questions. Let’s give it a quick start!

According to the CDC (centre for disease control), the laminar air flow principle was first developed in the early 1960s. It’s still incredibly relevant for modern labs, having literally shaped the way air safely moves in many generations of laboratory enclosures.

Table of Content

- Laminar Air Flow – Definition

- Components of the Laminar Air Flow Hood

- HEPA Filters – Crux of Laminar Air Flow

- Types of Laminar Air Flow Cabinets

- Classifications of Laminar Air Flow

- Conclusion

Laminar Air Flow – Definition

Laminar flow is defined as airflow in which the entire body of air within a designated space is uniform in both velocity and direction.

Laminar Hood sometimes also known as Laminar Air Flow is an enclosed bench designed to prevent contaminations like biological particles (SPM) or any particle sensitive device. This closed cabinet is usually made up of stainless steel without any gap or joints where spores might collect.

Air is drawn through a High Efficiency Particulate Air (HEPA) filter and blown in a very smooth flow or streamline flow (when a fluid flows in a parallel layer with no disruption between the layers)

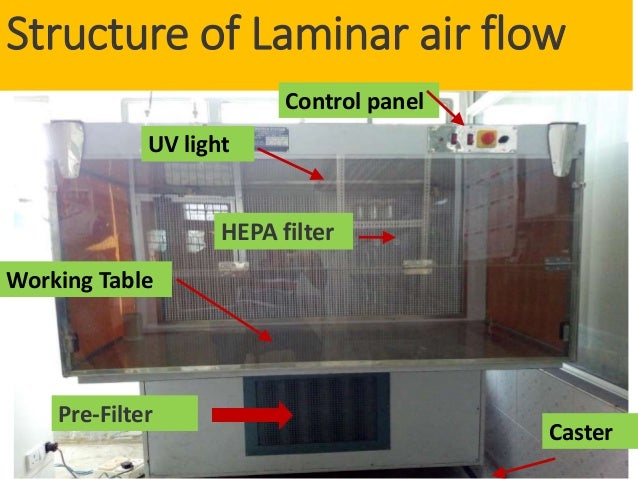

Components of the Laminar Air Flow Hood

Components of the Laminar Hood are

- A Blower/Motor system

- Pre-Filter-A fibrous washable filter sheet with large pore size and folded setup for high surface area to filter restrict the intake of suspended dust particles.

- High Efficiency Performance Air filter

- A Plenum Chamber (Pressurized housing containing air at positive pressure)

- Ultra Violet Light-ultra violet light is incorporated in the illumination panel of laminar air flow to take care of the sterilization of the existing air present in the enclosure, thus ensuring the high standard of cleanliness in equipment before the commencement of actual working.

HEPA Filters – Crux of Laminar Air Flow

HEPA (High Efficiency Particulate Air) filters- The HEPA filters are the crux of laminar air flow. The HEPA filters consist of a thin pleated sheet of boron silicate microfibers with aluminum separators. They are particulate filters which retain airborne particles and microorganisms (gases pass freely through). Filtration occurs by five distinct methods:

1) sedimentation

2) electrostatic attraction

3) interception (primary mechanism)

4) inertial impaction (primary mechanism)

5) diffusion (primary mechanism)

Laminar Air Flow Cabinets are suitable for a variety of applications and especially where an individual clean air environment is required for smaller items, e.g. particle sensitive electronic devices. In the laboratory, Laminar Air Flow Cabinets are commonly used for specialised work.

Laminar Air Flow Cabinets can be tailor made to the specific requirements of the laboratory and are also ideal for general lab work, especially in the medical, pharmaceutical, electronic and industrial sectors.

Types of Laminar Air Flow Cabinets

Laminar Flow Cabinets can be produced as both horizontal and vertical cabinets. There are many different types of cabinets with a variety of airflow patterns for different purposes.

- Vertical Laminar Air Flow Cabinets

- Horizontal Laminar Air Flow Cabinets

- Laminar Air Flow Cabinets and Hoods

- Laminar Air Flow Benches and Booths

All ensure a work space devoid of contaminants and may be tailored to the lab requirements.

Horizontal Laminar Air Flow Cabinets

Horizontal Laminar Air Flow Cabinets receive their name due to the direction of air flow which comes from above but then changes direction and is processed across the work in a horizontal direction. The constant flow of filtered air provides material and product protection. Since Horizontal Laminar Air Flow are designed such that the air flows directly at the operator hence they are not useful for working with hazardous specimens but are best protection for Tissue/cell culture.

Vertical Laminar Air Flow Cabinets

Vertical Laminar Flow Cabinets function equally well as horizontal Laminar Air Flow Cabinets with the laminar air directed vertically downwards onto the working area. The air can leave the working area via holes in the base. Vertical flow cabinets can provide greater operator protection. Vertical Laminar Air Flow Cabinets is best for working with hazardous specimens since the aerosols that are generated in the cabinet are filtered out before they are released into the surrounding environments.

Classifications of Laminar Air Flow

Laminar Air Flow

All the laminar air flows are classified into three broad categories as per US Federal Standards 209 B Ans 209 E (latest revision on 11.09.92). As per this standard the particle count in the existing air around the work table is taken into account.

Class 100

These laminar air flow units are those where the particle count of size 0.5 micron and larger is less than one hundred particle/ cubic feet, in the area of work.

Class 10,000

These laminar air flow units are those where the particle count of size 0.5 micron and larger, is less than ten thousand particle per cubic feet or sixty particle per cubic feet of dimension larger than five micron and bigger size in the area of work.

Class 1,00,000

These laminar air flow units are those, where the particle count of size 0.5 micron and larger is less than one lakh particle per cubic feet or seven hundred particles per cubic feet of dimensions five micron or larger in the area of work.

The difference between a laminar air flow hood and a biological safety cabinet can be summarized in the following points:

Laminar Air Flow Hoods

• Provide product protection only and must not be used when working with any form of biohazard or chemical hazard

• any potentially infectious aerosol that is created will lead to exposure of the operator and the environment

• Horizontal-flow clean air bench used for cell cultures can expose the researcher to aerosols of

allergenic or infectious materials.

• Vertical-flow clean air bench also blows air out into the room

Biological Safety Cabinets

• Provide personnel and environment protection and usually product protection

• Infectious agents must be used in a biological safety cabinet NOT a laminar flow hood

Conclusion

I hope now you are quite clear about a laminar airflow, its components and function. In case, you want us to give us feedback, you can leave a comment.

You can also read Autoclave.

I thought it was gonna be some boring old publish, but it in actuality paid out for my time. I will piece of writing a link to the page in my weblog. I am sure my personal guests will finally find that invaluable. . . .